Day 14 – Finishing the flywheel adapter

Finished the flywheel adapter today!

Just to recall, this is what we did on Friday:

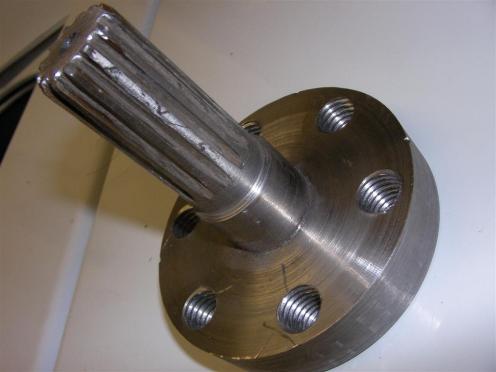

Then today, I created the splines. We didn’t have the exact spacing right, but it worked out in the end.

After that, I drilled the bolt circle using the mill – very easy to do, forgot to take a picture. Once it was done, I threaded the 6 holes by hand for the 1/2″ bolts we will be using.

Getting the adapter home, we crossed our fingers as we tried to fit it into the motors spline. It didn’t fit. I wasn’t discouraged though, I picked up the 110lb motor and threw it in my backseat. It was coming home with me tonight, and I vowed to get it right.

At first, I tried using a file. Didn’t work.

Then, sandpaper. Still no luck.

Then a dremel grinding bit. Nope.

Then… another dremel grinding bit. Nope.

Then, an engraving bit – almost did something, but still nothing really.

A drill bit used sideways! Nope. Even worse idea!

Finally, I got a dremel grinding disk going. I shaved down the edges of the splines as they weren’t pointy enough to slide into the motors splines. After a bit of grinding, I tried jamming it back into the motor. It got about 1/8th of an inch in. I took my hammer, and whacked it another half inch in. Prying it out, I saw exactly where the splines weren’t lining up. Turns out I did machine them a bit off, but that was okay – they were only off to one side. Repeating this process, I marred the spline I made with the motor spline to see where it wasn’t matching up – then I would grind down the edge until it slid in freely. Now its a nice snug fit! Even snugger then the original spline!

Kind of wish I was a bit more gentle with it. It’s been pretty marred up from prying it out of the motor spline and other stuff. Doesn’t look so freshly machined anymore.. More hand-made!

Next up, motor mounting plates and we’ll be able to throw it all in the hood! (well we still gotta paint it…)